Just because tomatoes are a healthy source of nutrition, drying is one of the common methods for preserving tomatoes and processing them into powder, which can be incorporated into soups and seasonings. Due to low investment and operating costs, hot air drying is the most widely used method for producing dehydrated vegetables and fruits. However, processing and storing fruits and vegetables at high temperatures can cause changes in physical properties and degradation of biologically active compounds, and therefore, the nutritional quality of the resulting products is reduced. The hot air drying of fruits and vegetables at different temperatures will affect the final moisture content and water activity of the product. The quality attributes of stored products are also closely related to the moisture content and water activity of the products. The drying temperature of the product can be considered a critical step because it can cause significant changes in the chemical and biologically active ingredients in the food.

A study has shown that convective hot air drying at a temperature of 60°C is the most effective temperature for retaining the highest bioactive components in sweet peppers and tomatoes. The drying temperature of 60°C is an important parameter, which affects the drying rate, the inactivation of polyphenol oxidase and the final water activity of the product, which significantly affects the better retention of phenol powder and flavonoids in the dry powder Sex, because it may be low temperature. Not enough to inactivate polyphenol oxidase.

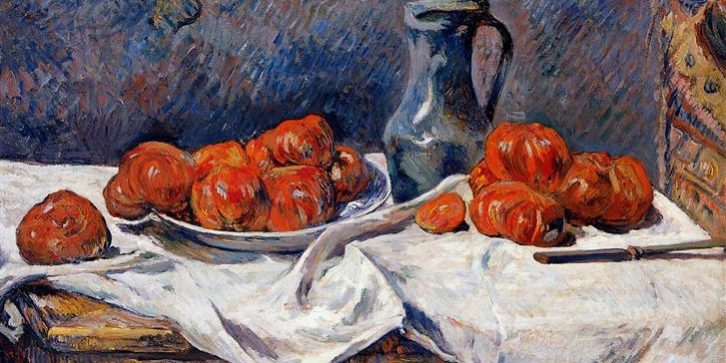

Tomatoes can be eaten raw or processed to reduce their high moisture content, which makes them extremely vulnerable to microbial degradation and decay. Therefore, they need to be preserved. Storage can extend its shelf life and improve its storage stability. In general, various methods are used to preserve it according to the world and the cost of preservation methods. Methods such as drying, canning, salting, use of lemon, freezing are usually used but concerns have arisen on the availability and retention of essential and beneficial nutrients in tomatoes after being made to undergo different processing conditions without defeating its aim of protection against diseases.

Thermal drying processing is now widely used to process tomatoes into cans, sachets, and other forms of products, thereby increasing their shelf life by reducing the moisture content that contributes to microbial decay.

References

Carotenoids and lycopene content in fresh and dried tomato fruits and tomato juice. A. Mendelová, M. Fikselová, Ľ. Mendel. 2013

Evaluation of the chemical composition and colour in long-life tomatoes dehydrated by combined drying methods. A.Jorge, D.M. Almeida,etc. 2014

Drying kinetics of tomato slices in vacuum assisted solar and open sun drying methods P. Rajkumar, S. Kulanthaisami,etc. 2007

Effect of drying temperatures and storage on chemical and bioactive attributes of dried tomato and sweet pepper. Ramandeep Kaur,Kamaljit Kaur,etc.2019

Ultrasound assisted extraction of lycopene from tomato processing wastes. S. Kumcuoglu, T. Yilmaz, S. Tavman

Microencapsulation by spray drying of a lycopene-rich tomato concentrate: characterization and stability. A.K. Singh, N. Sharma,ect. 2017